Necessary product for some customers

The hair extension boxes can be seen in a lot of cosmetic stores. Usually, these types of products are available in most of the stores. The boxes for hair extension are small and slim in size. These are simple products that do not require any special treatment. In simple plastic boxes with good printing, these products are ready to be sold in the market. The hair extension boxes are sold all over the market as well. These boxes can be sold individually or they can be sold in wholesale.

If bought in whole sale there is considerable discount on the purchase amount of the boxes. These boxes are available in all types of color and sizes. Depending on the manufacture and the type of product that needs to be packaged in the box, these boxes can be even custom made. The common thing that is seen on the outside of all the boxes of hair extension products, is the name and logo of the company that makes it.

Custom Buy Boxes makes the product recognizable and the customers can rely on the brand rather than experimenting with different products. The product boxes are the first thing that the customers look at when they are buying the product. These boxes play a vital role in the sales of the products. The hair extension boxes are bought by the companies to put their product in, if they do not manufacture their own boxes.

Focusing on the demographics

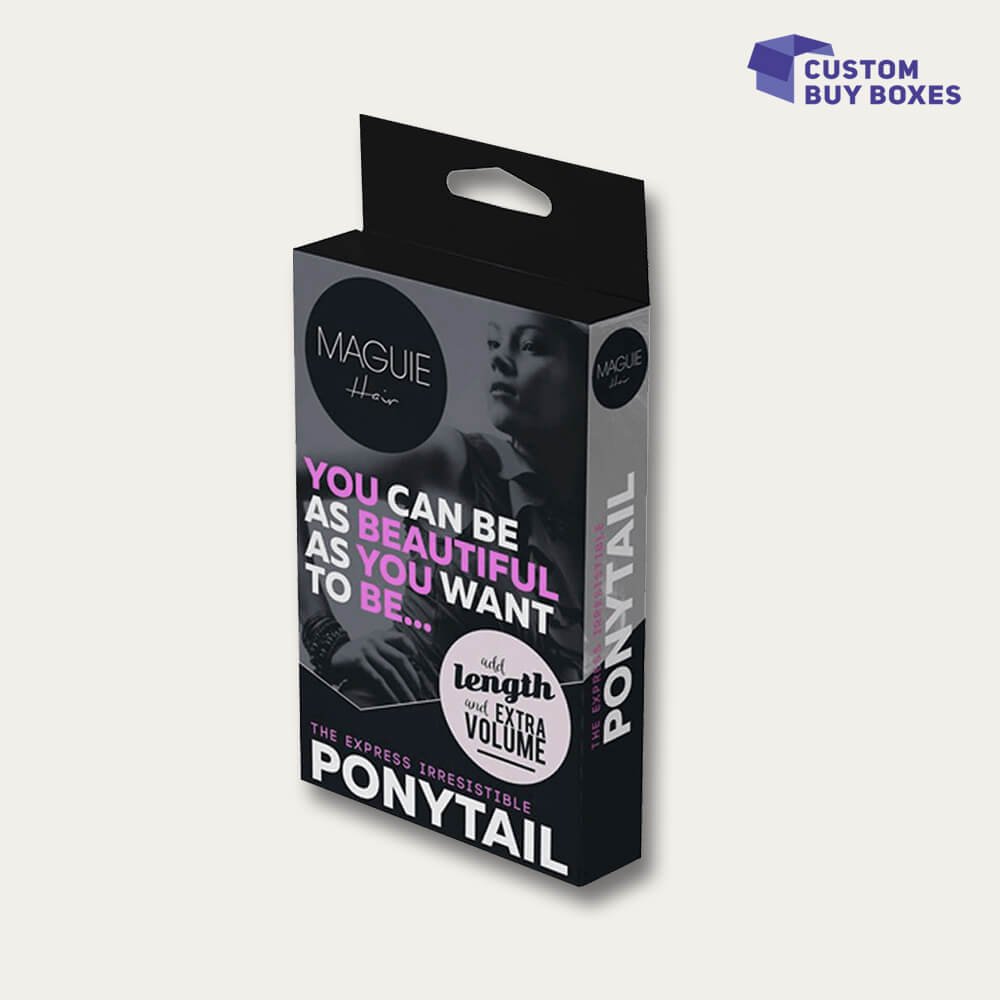

The manufactures who make the hair extension product mainly target their attention on the female customers. It is rightfully so because generally women are the ones who need hair extension to make their already long hair even more long and dense. The hair extension products and packaging are made with this in mind. It is for this reason that most of the hair extension products have the picture of the female models on it to attract more customers.

The modelling pictures play two parts, the first one is the display of the product result and the other is to attract the customers to get the product because of their favorite model’s testimonial. The printing of the advertisement and the testimonials on the packaging is very common these days and most of the manufactures like custom buy boxes use these pictures on their product packaging.

There can be other inks used like the elevated ink to make the box and the packaging appear unique among all the other products of the same type. Anything unique in the product packaging is bound to get more attention from the customers. If the customers rely on the product packaging as the standard of the product’s quality they could be misled because it is not always the case. The product and the packaging do not have to necessarily share the same type of quality but the better the packaging is the more customers would trust the product for the first time.

Using the right material

The reason for this is simple and the same packaging for the hair extension can be used to store the product after using. It would keep the product safe and secure and ready to be used next time whenever the customer wants. The other types of packaging that use the cardboard or other types of boards, are commonly used for the disposable products. The hair extension that the customer does not use again or rather cannot use again are supplied in those boxes.

These packaging can be even in the plastic wrappings and this makes it even easier to look at the product from inside the packaging. The customer can get an idea of the length and the color of the hair extension before buying the product.

This can be a benefit for the customer and the manufacture both. The manufacture can display their product with minimal effort and their cost of the packaging will be reduced as well. On the other hand, for the customers, they can take a look at the product and its features before paying for it.

Packaging can deliver the product image

No matter what the material used in the hair extension products, people who need it will buy it. This does not mean however that the manufactures and the brands can sell their product in any type of packaging. The packaging in this case can be minimum and this play in favor of both the customer and the manufacturer.

There are other cases when the hair extension products are ordered online. The boxes that are used in the delivery of the hair extension products are different from those which are sold in the stores. This is because the main purpose of the delivery boxes for the hair extension products is to keep the product safe and secure rather than display it in the store.

Depending on the purpose of the packaging the box and the wrapping of the product can change. Knowing when to use which packaging can make a huge difference in the sale of the product. It can make the product an all-time favorite or people can ignore it completely.

Reviews

There are no reviews yet.